This post draws heavily from an article on EE Publishers titled “Solar PV tracking can increase output” published on April 14th 2016. The article can be found here, and its recommended to read if you are unfamiliar with sun tracking technologies or solar principles in general.

One key metric for PV performance is Yield, which when measured in kWh/kWp per year allows for an indication of how much energy the system will supply over the course of a year with regards to its size. This is useful as it removes the impacts that seasonality has on the system production. It also aids in financial decisions because most installers will quote a price with regards to the kWp of the system.

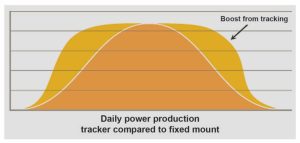

A quick logical conclusion to draw and have in mind for the context of this article is that making a PV system with single axis tracking will have a higher yield than one without, but it will also have a higher cost per kWp. Due to the increased need for maintenance and also the space requirements for a single axis system, it isn’t usually a worthwhile upgrade unless the system in question is larger than a few MW. As a note: single axis tracking can increase solar yield by up to 20%, and here in Gauteng, South Africa the yield for a very optimal, fixed tilt plant can reach up 1800kWh/kWp per year. Which equates to 4.93 kWh per kWp per day. The power production difference between a tracking system and a non-tracking one is noted in the figure below. (Credit: First Solar, “The First Solar tracker: Increasing energy output and reducing LCOE” )

On the same note of increasing cost for increased utility we have to discuss battery systems and going off grid. The first thing to understand is that batteries are not cost-effective; at their current (2018) price point and life span, any batteries installed will need to be replaced before they pay themselves off in energy savings. The second point is that batteries are necessary if the desire is to go off grid and the only energy generation is from PV (assuming that other forms (generators) detract from renewable goals).

On the same note of increasing cost for increased utility we have to discuss battery systems and going off grid. The first thing to understand is that batteries are not cost-effective; at their current (2018) price point and life span, any batteries installed will need to be replaced before they pay themselves off in energy savings. The second point is that batteries are necessary if the desire is to go off grid and the only energy generation is from PV (assuming that other forms (generators) detract from renewable goals).

There are 2 approaches that can be taken when going off-grid. One, is to sufficiently oversize the battery such that it would be able to supply energy for multiple days regardless of the weather. Two, is to cycle the battery every day to get full utilization from it. The second way is more cost effective as a smaller battery is needed, but the downside is that there is very little security of supply and a few days of poor weather would see a loss of energy supply. If the battery is oversized, as per method one, then the impact of single axis tracking on the project cost is negligible as the battery is specifically scoped for days of little to no sunlight. For this reason, the logic discussed next applies only to the battery cycling set up.

The logic is as follows: the user has a specific energy demand over the course of 24 hours, for example, let’s say 100kWh. An installed PV system will have to generate the entirety of that energy, and based on a daily yield of 4.93kWh/kWp the system will need to be approximately 20kWp. Of course, the solar will only be able to provide adequate power for about 25% of the day and thus the battery will need to supply the other 75%. This means that a 75kWh battery is required (and in reality, even larger to avoid complete discharge). With single axis tracking in place the yield increases by 20%; meaning firstly that only a 16kWp system is needed, but more interestingly the amount of time that the solar can provide power can increase to about 30% which results in a slightly smaller battery (70kWh). If we assume that the cost of a battery is linear with relation to size and that adding single axis tracking doesn’t increase the cost (because fewer panels are being installed) then this results in a 6.5% price reduction for the system. This may be small, but any cost savings will enhance the business case for going off grid.