Drinking water is becoming an increasingly scarce resource in South Africa, and Gauteng has been hitting the headlines most recently due to the number and duration of water supply interruptions being experienced. Interestingly, the water shortages are not so much because of inadequate raw water supply from the storage dams, but because of failing supply and delivery infrastructures within the cities. The failing infrastructures are, however, having a significant negative impact on the storage dam reserves.

A common industry benchmark to measure the efficiency of the water supply network is the percentage of Non-Revenue Water (NRW) that is lost before delivery to the consumer. The losses are typically due to leaks, theft, and metering faults. Most provinces lose more than a third of their water supply. The international benchmark is below 30%, and only the Western Cape is inside the benchmark at 29.6%. Gauteng is second best at ~40% – the rest of the provinces are far worse.

The purpose of this article is not to look at the greater supply issues and the NRW challenges faced in the cities, but will look at the water use on the consumer side of the meter – particularly at schools.

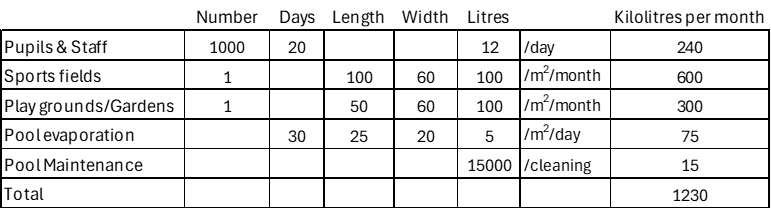

Schools are large communities and the primary need for water is for healthy sanitation. The basic water consumption for the school’s operation is quite easily modelled based on the pupil and staff complement at the school. A study was conducted in 2004 for the Water Research Commission at a number of Gauteng schools. In the study the water usage in Ekurhuleni schools ranged between ~3 and 113 litres per learner per day, and the average was 23 litres/learner/day. Following a water saving initiative at the time that included repairing leaks, replacing washers, modernizing toilet cisterns to dual flush, replacing automatically flushing urinals with manually operated push button systems and replacing conventional taps with push button taps, the average water usage dropped to 12 litres/learner per day. There was quite a large range in perlearner consumption of water, but all schools successfully reduced their consumption.

School facilities and amenities are major drivers for the total water demand. Landscaping and sports field irrigation can be significant water users depending on the season and the rainfall pattern.

Sports fields, which are typically 6000m2 each, require 25 mm of precipitation per square metre per week during the growing season. This equates to ~ 600 kilolitres of water per field per month. Thankfully, Gauteng is a summer rainfall area, and sports fields are not always dependant on the municipal supply.

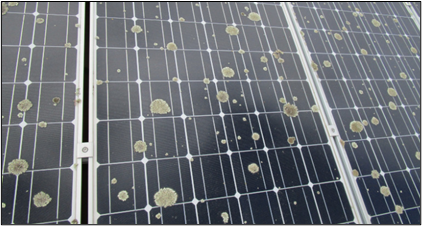

Swimming pools are large users, or losers, of water. The typical 25-metre school swimming pool has a surface area of five hundred square meters and a volume of about 800 000 litres. The typical water evaporation rate in Gauteng is five millimetres per day. Five millimetres evaporation is five litres per square metre per day, i.e. 2.5 kilolitres per day from a typical outdoor 25-metre school pool. Swimming pool maintenance requires backwashing of the filtration system on a frequency dependant on the swimmer numbers and frequency will vary seasonally – typically it is a monthly requirement and will dispose of 15 kilolitres of water per occurrence.

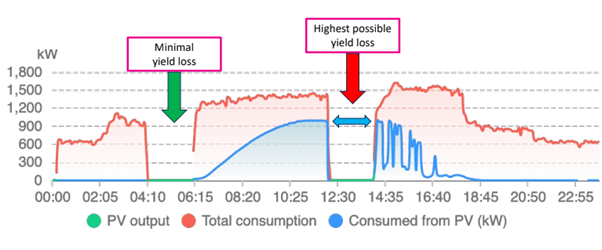

So then, collating these benchmarks, we can build up an estimate for a monthly water usage profile of a school. Let’s take a look at a modelled day school with a learner complement of 900, and staff of 100; one grassed sports field; and an outdoor 25-metre swimming pool.

* In this simple model for now we assume no on-site boarding or live-in scholars.

Every school will have its only benchmark based on the facilities and the activities at the school. The benchmark illustrated here is probably a peak benchmark, and it will vary seasonally. The adage of what is measured can be managed, and comparing monthly water billing to a calculated benchmark will provide some comfort to the school of being under control or raise the alarm that there is water loss, and an associated cost.

Water is a vital resource but also a significant expense for schools and universities. Many educational institutions fail to realize how much cost they can save by reducing their water consumption and improving water management and efficiency.

Water and sewer tariffs are increasing and, no doubt, will start following the electricity escalation trend. Bear in mind that municipal billing assumes incoming water is also outgoing water, i.e. the sewer tariff is applied to the incoming water volume – water used for irrigation and loss due to evaporation is billed in the sewer billing.

Either way, this typically means schools and universities must expect to pay much higher rates for water and sewer services in years to come.

There is good news though. There are ways administrators can reduce or mitigate these cost increases. The answer is water efficiency.

Understanding Water Efficiency

Some of us may wonder what the difference is between water conservation and water efficiency. Water conservation refers to reducing consumption briefly, such as during a drought.

Water efficiency, on the other hand, means reducing water consumption permanently, often by turning to technologies designed to use less water. For example, the use of pool blankets /covers can assist in not only reducing evaporation losses, but also the loss of heat in the case of heated pools.

We should note that how water-efficient an organization is assessed to be can also be an indicator on the inherent efficiencies of the organization in other aspects of its operations.

Water waste and other environmental waste are signs of inefficiency in [an organisation’s] production and management.

How to Start

To start the process of using water more efficiently, administrators must collect two or three years of water utility bills to determine how much water the school uses and what it pays. Now, we have a benchmark against which to mark our progress. From here, we take the following steps:

Administrators should set water-reducing goals versus the theoretical benchmark discussed earlier in this paper. Water reduction over a defined period of time. Having goals helps keep the journey focused.

We reach those goals by conducting a water audit to determine exactly where water is being used on the campus.

With the audit completed, the deviations from the theoretical benchmark will highlight the areas of opportunities – for example, landscaping and restrooms.

Landscaping

Among the steps administrators can take to reduce water consumption for landscaping and vegetation, the following are noteworthy initiatives :

- Install native vegetation. This refers to plants, trees, shrubs, and other vegetation customarily found in an area.

- Ensure plants are clustered; bunched together, they save water.

- Reduce mowing frequencies; set mower blades higher to help keep the soil below moister.

- If sprinklers are installed, ensure they are on timers and do not irrigate nearby sidewalks and streets.

Restrooms

A few initiatives with toilets and urinals can bring surprisingly meaningful results. Newer dual-flush toilets are mandated to use 9 litres per flush or 5 litres per half flush. However, as toilets age and undergo repairs, they may use more than these amounts.

Administrators should replace toilets every six to seven years. This replacement will help ensure lower consumption, and many manufacturers are now making toilets that use less than the 9 litres of water per flush.

New urinals must use no more than 4 litres of water per flush. However, due to purchasing and cost factors and a desire to reduce water consumption even further, many facilities are taking the next step and installing waterless urinals.

These systems use no water, require less plumbing, do not require flush handles or sensory flush systems, and have few, if any, service requirements, all of which make them more cost-effective to install and use.

The Next Step is Yours

Let’s remember that there are ways to reduce water consumption in schools, universities, and all facilities. The technology is available and constantly improving. The next step is yours: take the steps discussed here and realise the savings.